Conveyor belt

Three models, infinite possibilities

Reliable, modular, and designed to deliver excellent performance year-round, our conveyor belt is the ideal solution for a wide range of applications—from transporting people to carrying sports equipment such as canoes, bicycles, and inflatable boats.

Thanks to its robust and modular structure, it can easily reach lengths of over 400 meters, ensuring continuous operation 365 days a year, even in the most challenging environmental conditions.

With an adjustable speed ranging from 0.2 m/s to 0.7 m/s (with an option up to 1.2 m/s) and three available widths (650 mm, 810 mm, and 1200 mm), it is perfectly suited for tourist facilities, amusement parks, sports complexes, ski resorts, and more.

Every detail is designed to offer maximum safety, comfort, and flexibility for both operators and end users.

To address specific market demands, three distinct models have been developed: Start, for those seeking an essential and functional solution, Easy, designed for greater versatility, and Premium, which represents the pinnacle of performance.

Main Applications

Ski Resorts

Ideal for transporting skiers quickly and efficiently

Ski Schools

A valuable aid for beginner skiers during lessons, facilitating easy ascent

Ski Domes

An essential component for uphill transportation in indoor artificial ski facilities

Ski Jumping Facilities

Extremely important for athlete training in ski jumping facilities

Mountain Bike Park

Perfect for the transportation of bicycles and integrable with belt cleaning systems

Amusement Parks

Widely used in summer at water parks

Tubing

Used for transporting tubing, sleds and other sports equipment

Parking areas

Perfect for transporting pedestrians and skiers between parking areas and ski facilities

Dry Slopes

An ideal support for uphill transportation in the presence of artificial ski slopes

Sport Facilities

Indispensable in water spots for the ascent of canoes and/or rafts

The distinctive features

of our product

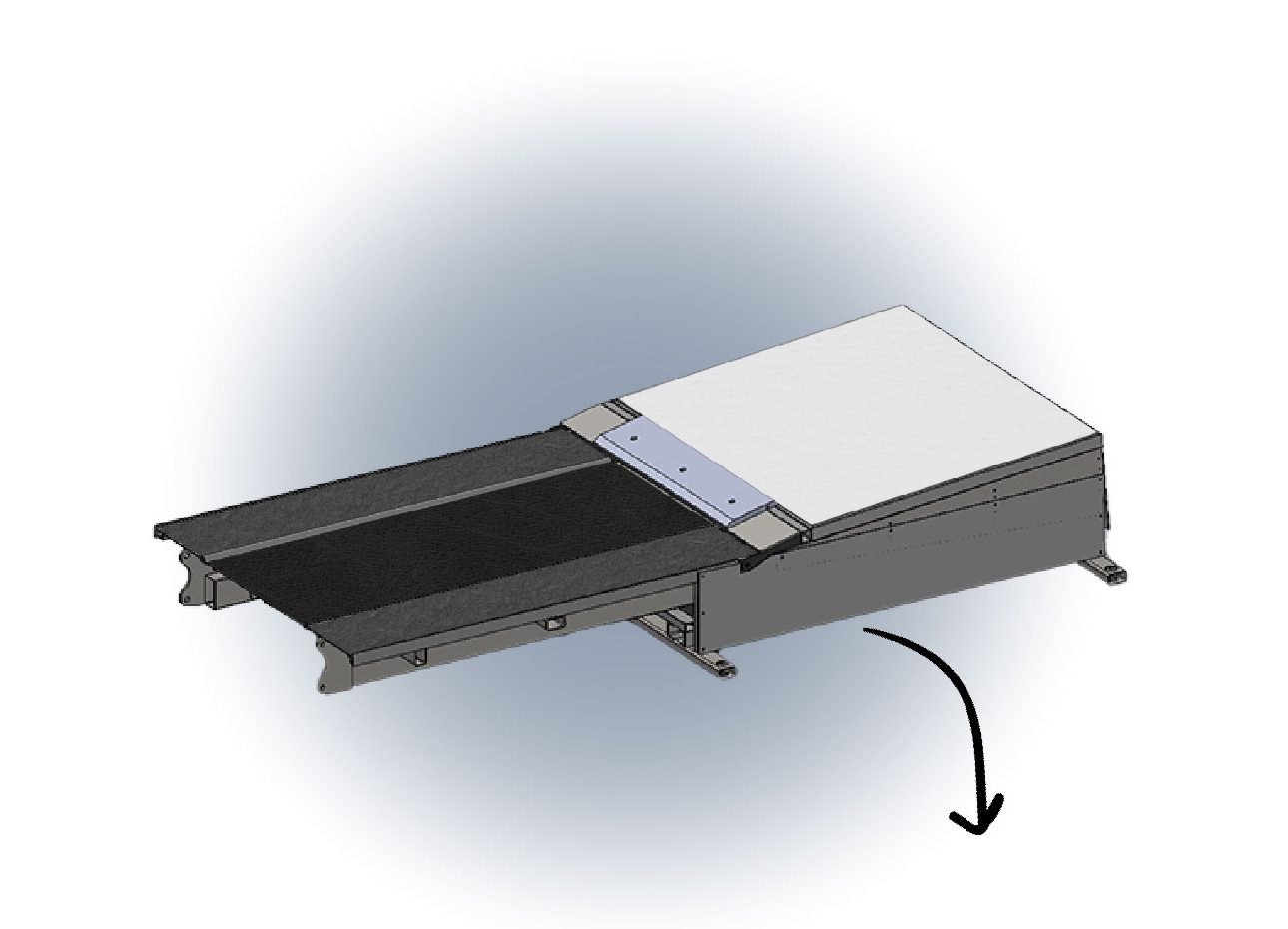

- High-quality galvanized steel frame, engineered to ensure maximum resistance to weather conditions and long-lasting durability, even in challenging environments.

- Side PVC covers provide a practical and effective solution for keeping the area beneath the belt clean.

- Height-adjustable support feet allow for quick and precise ground installation, adapting perfectly to various types of terrain.

- Stainless steel sliding tanks ensure exceptional wear resistance.

- Modular assembly system designed to optimize installation times, allowing for quick and easy setup.

- Side walkways made of fiberglass with non-slip coating—a combination of materials that ensures durability, lightness, and safety. The non-slip surface provides excellent grip, even in wet or icy conditions, ensuring enhanced user safety.

- Rubber belt with customizable shortening option—an important advantage for maintenance and operational flexibility, ensuring the belt always remains in optimal condition.

- Built according to EN15700 standards, and fully compliant with all current European regulations regarding operator safety during maintenance operations.

- Certified according to international standards ANSI B77.1 and CSA Z98, and CE marked.

1. The Premium Model

An unparalleled technological evolution

The Premium model represents the top-of-the-line of Team Service conveyor belts. Premium lift systems can reach lengths of over 400 meters and are available in three widths (650 mm, 810 mm, and 1200 mm). The model is distinguished by its extremely advanced and innovative technology. There are indeed multiple software functions available, controllable directly from the touchscreen located upstream of the system.

The Premium Model Industry 4.0 certified (only available in Italy), with the possibility of recovering 20% of the investment over three annual installments, directly offsetting credits from taxes, contributions, and VAT payments.

What applications is it most suitable for?

The Premium model has no usage limits. It is indeed the ideal solution for any type of need, from simple to more complex ones.

Technical data of the TS-Premium model

- Minimum length 6 metres

- Maximum slope of 25%

- Adjustable speed from 0.2 to 0.7 m/s

- Available in three widths (650 mm, 810 mm, and 1200 mm)

- Rubber belt width 600 mm, 760 mm or 1150 mm

- Hourly capacity of 1,260 people (2,520 people for the 1200mm) at a distance of 1.5 metres from person to person

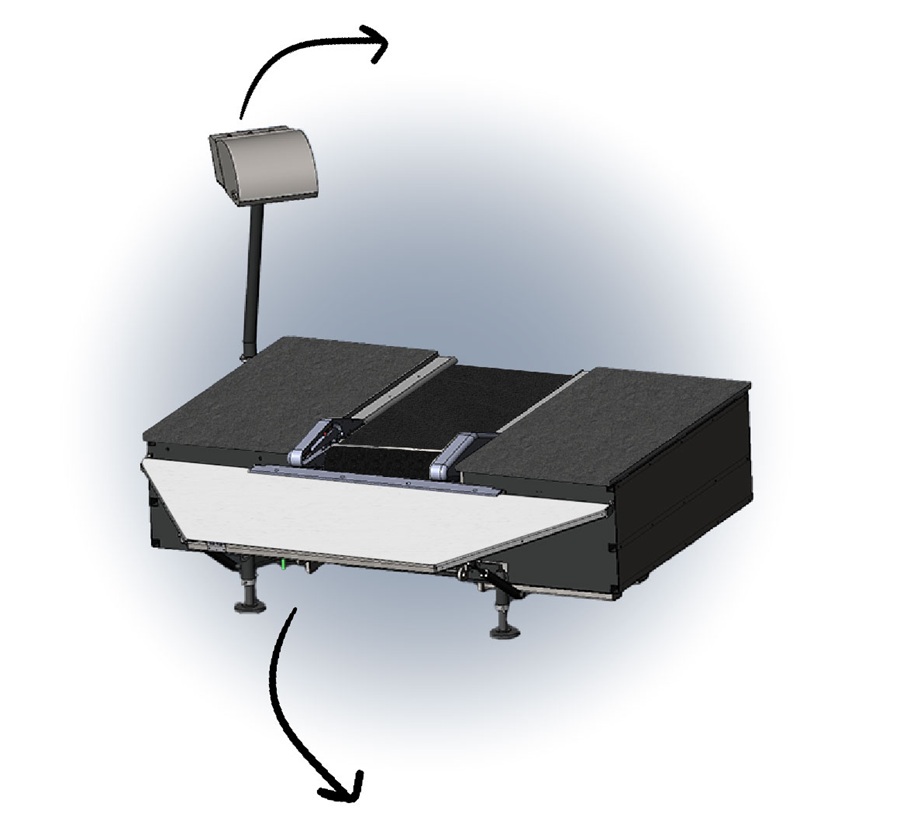

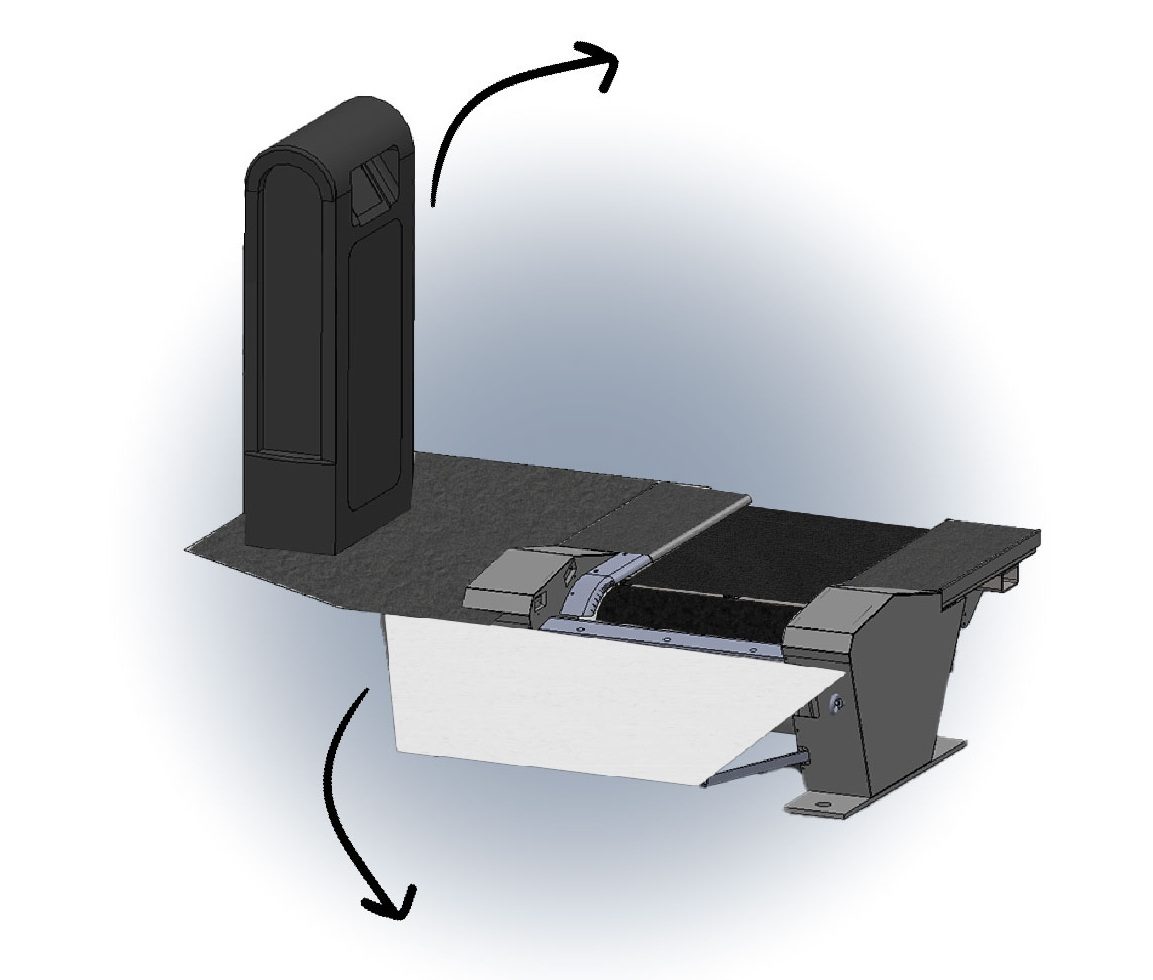

Control Column and Touchscreen

The control column is the fundamental and distinctive component of this model. It has a 12.1″ anti-glare, high-brightness touchscreen installed on it, which, when not in use, is protected from the weather by a lift-up cover.

From the touchscreen, you can manage the multiple functions of the system easily and immediately check for any malfunctions.

From the home page, you can choose or modify the language and speed of the system, display data such as the current day and time, outside temperature, rubber belt voltage, amperage, consumption, and engine temperature.

Control Column and Touchscreen

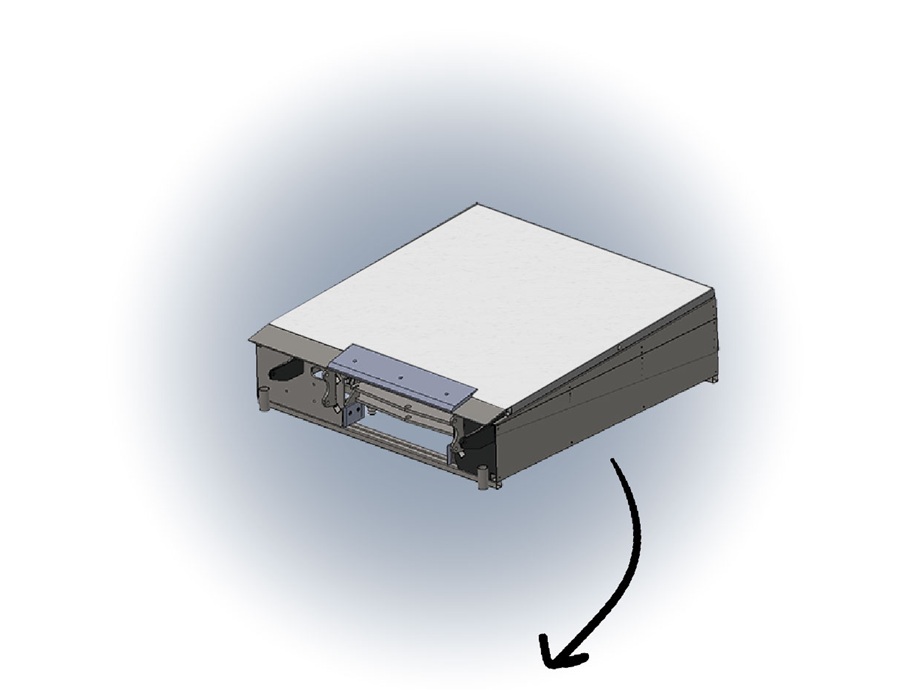

Motor Station

Return Station

Software: Key Features and Functions

- The “snow removal function” enables quick carpet cleaning after snowfall. In this way, the snow is brought to the top and, by placing a snowplow near the exit, it can be removed quickly and effortlessly.

- The "ice-breaking function" automatically removes ice between the rubber belt and the side platforms. By activating this function, the belt will move back and forth, in both directions.

- The "anti-ice function" can be activated at the end of the day when the conveyor belt is no longer in use. The belt will move automatically during the night, preventing the formation of ice.

- It is possible to monitor in real time the status of the belt's safety systems and precisely identify any error causing a shutdown. At every system stop, the type of malfunction and its location will be displayed on the touchscreen.

- The system displays and saves various information such as the number of people transported, hours of use, KW used, and motor amperage. This information is provided on a daily, weekly, monthly, and yearly basis. Using a USB key or connecting to the system with a PC, it is possible to download all of this data.

- The system can be connected to the internet. This allows for remote assistance via tele-support whenever needed. This service proves to be very useful in quickly resolving most of the operating problems that may arise. No additional costs are required, only a stable connection provided by the customer.

2. The Easy Model

A guarantee of versatility

The Easy model can be used in different contexts, from smaller to more complex systems. The customer has the option to choose from three available widths (650mm, 810mm, and 1200mm). The operator can adjust the speed of the system up to a maximum of 0.7 m/s, optionally up to 1.2 m/s.

What applications is it most suitable for?

The Easy model is suitable for all types of applications, with a maximum length of up to 150 meters.

- High safety for users and operators

- Speed adjustable at the operator’s discretion

- Operable 365 days a year, both in summer and winter

Technical data of the TS-Easy model

- Minimum length 6 metres

- Maximum slope of 25%

- Adjustable speed from 0.2 to 0.7 m/s

- Available in three widths (650 mm, 810 mm, and 1200 mm)

- Rubber belt width 600 mm, 760 mm or 1150 mm

-

Hourly capacity of 1,260 people (2,520 people for the

1200mm) at a distance of 1.5 metres from person to person

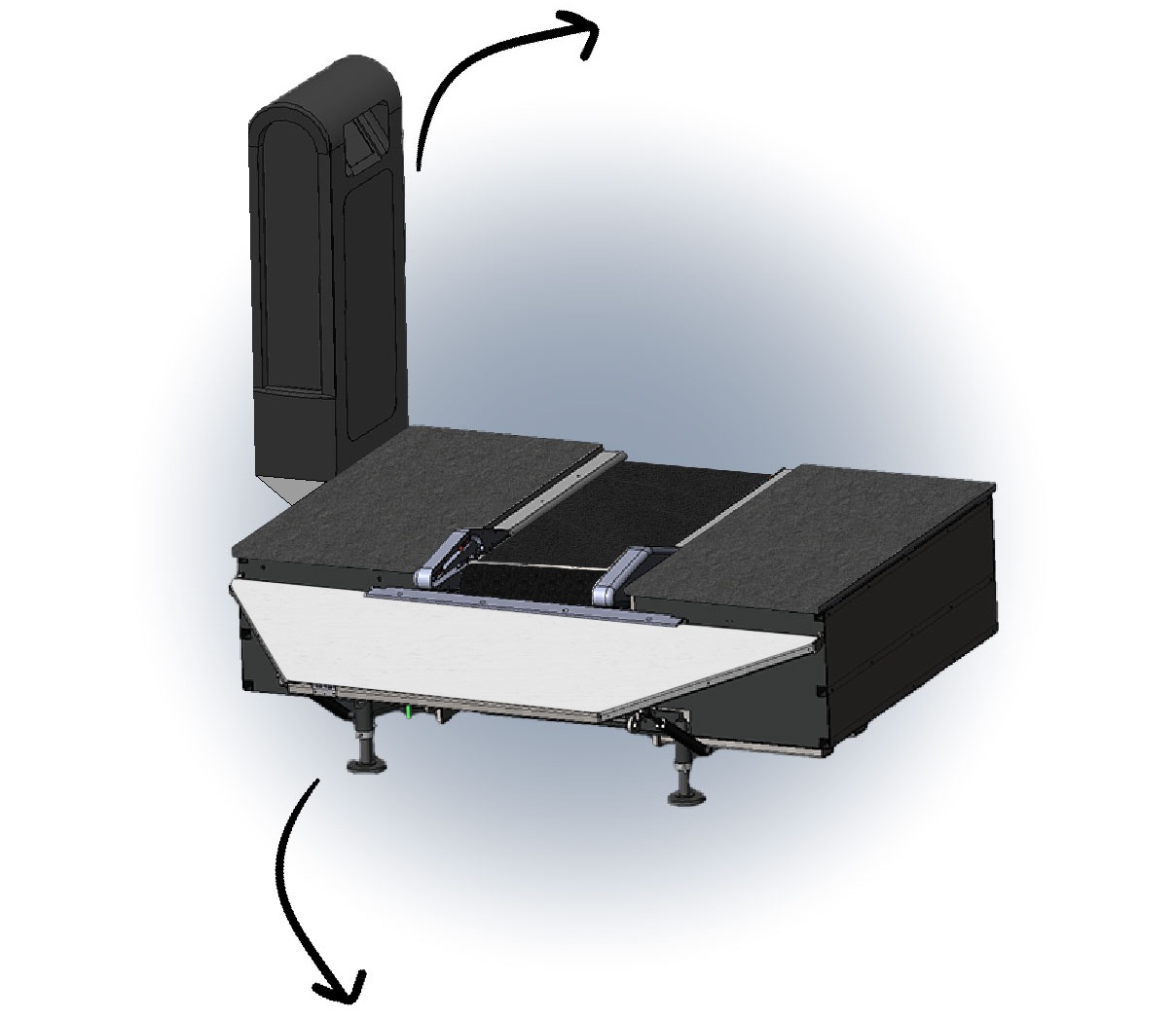

Control Column and Touchscreen

The control column is made from a weather-resistant plastic mold, housing the belt’s electronics for quick and easy access.

The control column features a 3.5ʺ touchscreen with a liftable cover, enabling easy management of system functions and immediate troubleshooting of malfunctions or stoppages.

Control Column and Touchscreen

Motor Station

Return Station

Software: Key Features and Functions

- From the touchscreen, it is possible to turn on and off the infrared resistance. It is also possible to control the resistance through a timer, choosing a preset operating period for its activation and its relative shutdown.

- It is possible to view the report of the number of people transported daily and those transported since the start of the system's operation.

- By selecting the corresponding icon, it is possible to view the working hours of the conveyor belt.

- It is possible to view in real-time the status of the safety systems of the conveyor belt and accurately identify the error that blocks its operation. At each system stop, the type of error will be displayed on the touchscreen. It is also possible to view the inputs of the safety PLC.

3. The Start Model

Simplicity for everyone

Extremely simple and intuitive to use, the Start model is available exclusively in a width of 650mm. This model has been specially designed for customers who need a quality conveyor belt, with a maximum length of 42 meters and at an affordable price.

What applications is it most suitable for?

- Perfect for ski schools that require a product that is simple and safe to use for beginners’ lifts.

- Suitable for small ski resorts looking for a conveyor belt of up to 42 meters in length at an affordable price.

Technical data of the TS-Start model

- 7,1 kW gearmotor

- Minimum length 6 metres

- Maximum slope of 20%

- Adjustable speed from 0.2 to 0.7 m/s

- Available in 650 mm width

- Rubber belt width 600 mm

-

Hourly capacity of 1,260 people (2,520 people for the

1200mm) at a distance of 1.5 metres from person to person

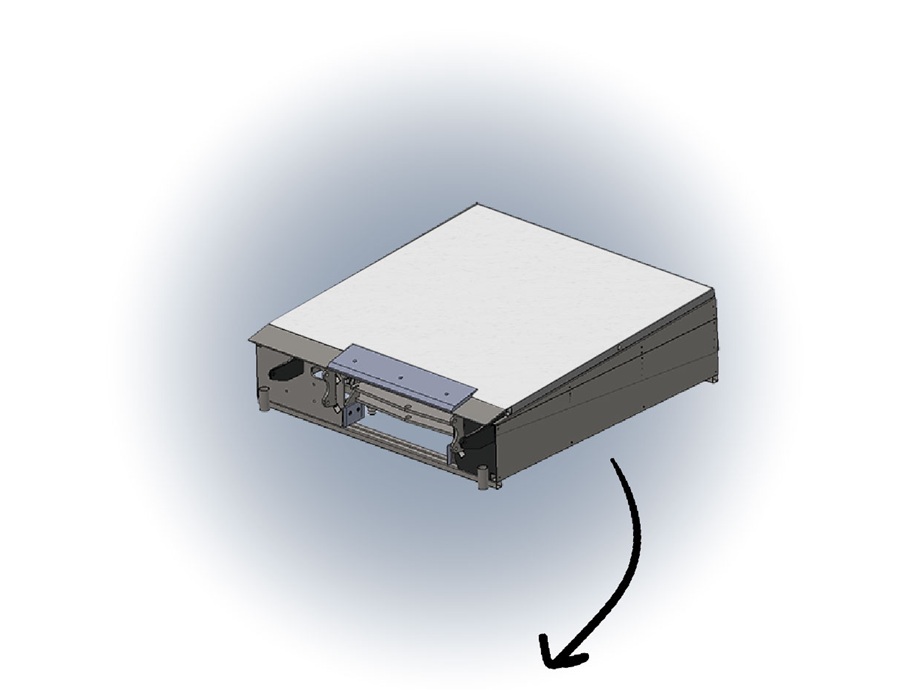

Control Column

Control Column

Motor Station

Return Station

Rubber belts

The two available models

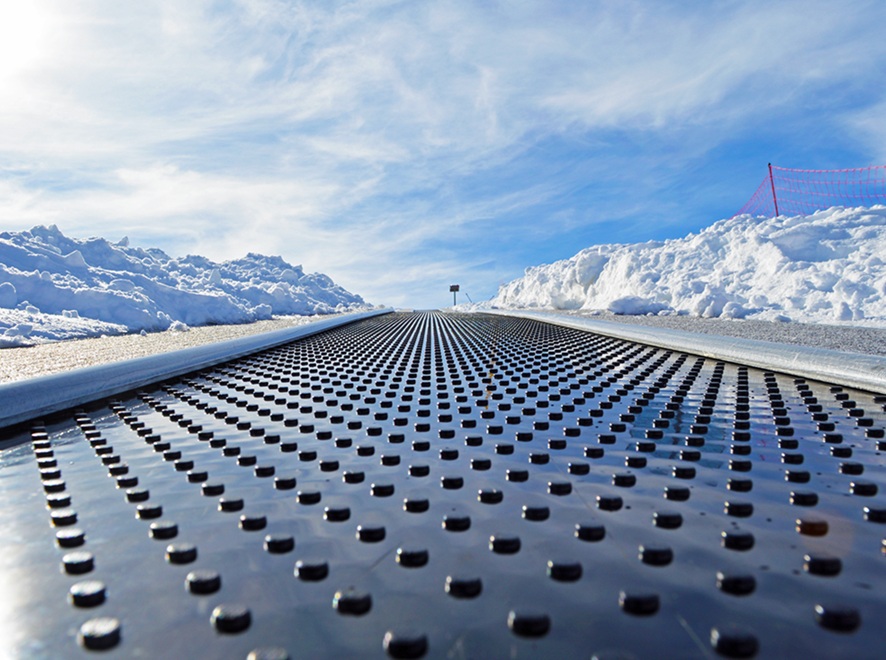

Top Grip

The Top Grip belt ensures optimal grip in various operating conditions. The lower layer has a special resin finish that makes it waterproof, while the upper layer ensures optimal grip with skis, shoes or boots. The cylindrical surface allows skis to always have a direct support surface on the rubber, even when there is snow on its surface.

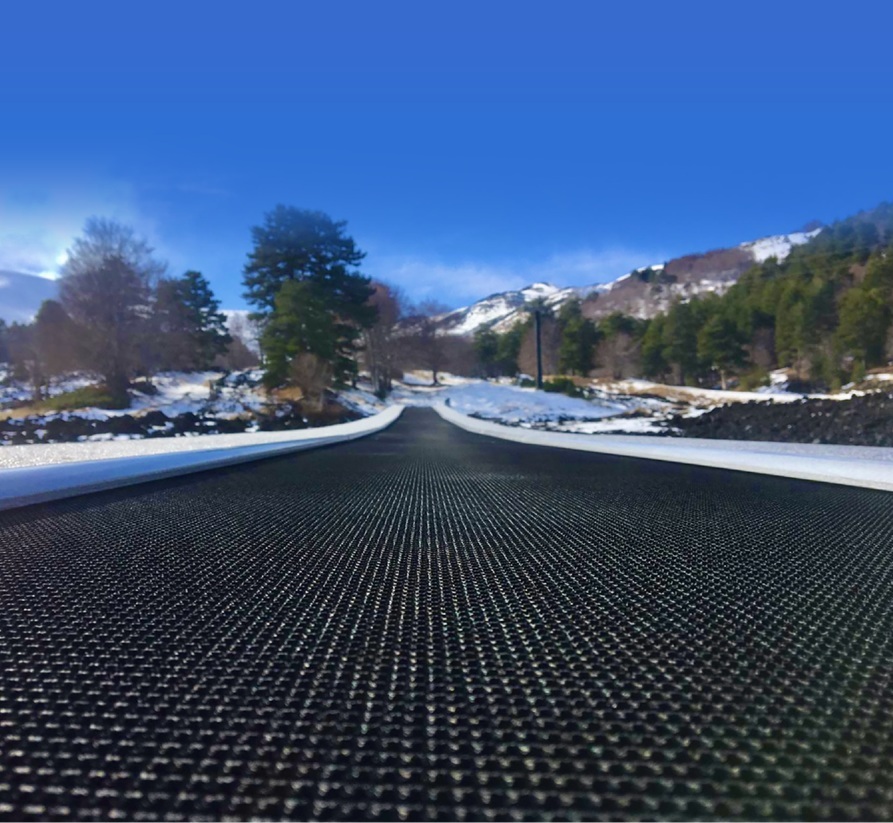

Bee Nest

The Bee Nest belt is characterized by its distinctive honeycomb surface. It has good resistance to abrasion, tearing, and high resistance to atmospheric agents. The composition of the weave guarantees an extremely low longitudinal elongation.